- Products

- Thermowood

The Long Lasting and Sustainable Solution

Thermowood production – as scientifically based industrial timber modification – has been in active use for more than few decades, while in recent years its demand has gained surprising momentum. The context of sustainability and green economy leaves no doubt about the unique advantages of this modified timber.

Thermowood is essentially natural wood, processed with heat (180–215°C), steam and water in specifically adjusted and controlled heating cycles. Being entirely ecological and free of any chemicals, the treatment process irreversibly modifies physical and chemical properties of timber resulting in extremely durable and exceptionally sustainable material, friendly to both humans and nature. The modification also improves its dimensional stability and thermal insulation qualities.

Unlike ordinary wood, Thermowood contains no natural resins nor formaldehydes. It has a pleasant scent, its weight is lighter, and texture subtler, smooth to touch. After undergoing a full processing cycle, ThermoWood acquires its typically warm caramel tint. The surface can be safely exposed to the elements outside, although, with time, the natural UV radiation will transform the colour to greyish hue.

Thermowood is irreplaceable in environments with dramatic temperature and humidity fluctuations, which makes it an ideal material for outside cladding, decking, balconies, fences, and saunas. Due to its aesthetically pleasing appearance, eco-friendliness, and dimensional stability, Thermowood is an increasingly popular choice in contemporary interior design.

We have been specializing in thermally modified timber since 2009, and our top-notch, CE certified BROLIS TIMBER thermotreatment plant has been running full speed since 2022. We offer You premium sustainable Thermowood products, designed and manufactured in accordance with the highest technological and sustainability standards of the European Union, using carefully selected PEFC-certified raw material, mainly Nordic pine. We can also offer niche products made of thermotreated alder or aspen.

Our manufacturing process takes place in a strictly controlled environment and is set to the highest standards of quality in accordance with the technology developed by the Technical Research Centre of Finland (VTT). With fifteen years of experience in Thermowood development and production, we can confidently offer You the best products on the market.

The Advantages of Thermowood

(Family villa in Giruliai. Project: DO ARCHITECTS. Photo: Laimonas Ciūnys, 2018)

Durability

Exceptional durability of Thermowood derives from its degraded carbohydrates – mainly hemicellulose and cellulose, which serve as food for rot-inducing fungi, bacteria, and beetles.

This advantage is enhanced by significantly reduced equilibrium moisture content. Saprotrophic fungi become active when the timber’s moisture content exceeds 20%. Irrespective of air’s relative humidity, the equilibrium moisture content of thermally modified timber always remains significantly below 20%. This has a huge impact on the timber’s long-term durability.

That is why, in outdoor conditions, thermally modified pine or spruce cladding can last for over three decades, and decking will serve at least 15-20 years, service time being shorter due to higher mechanical wear and loads.

Note

Thermowood product surface is still susceptible to mould, as these microorganisms are capable of feeding on airborne particles. This has no impact on the structure of wood. Yet, it could be considered an aesthetic defect. The formation of mould can be avoided through coating and regular maintenance.

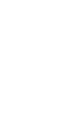

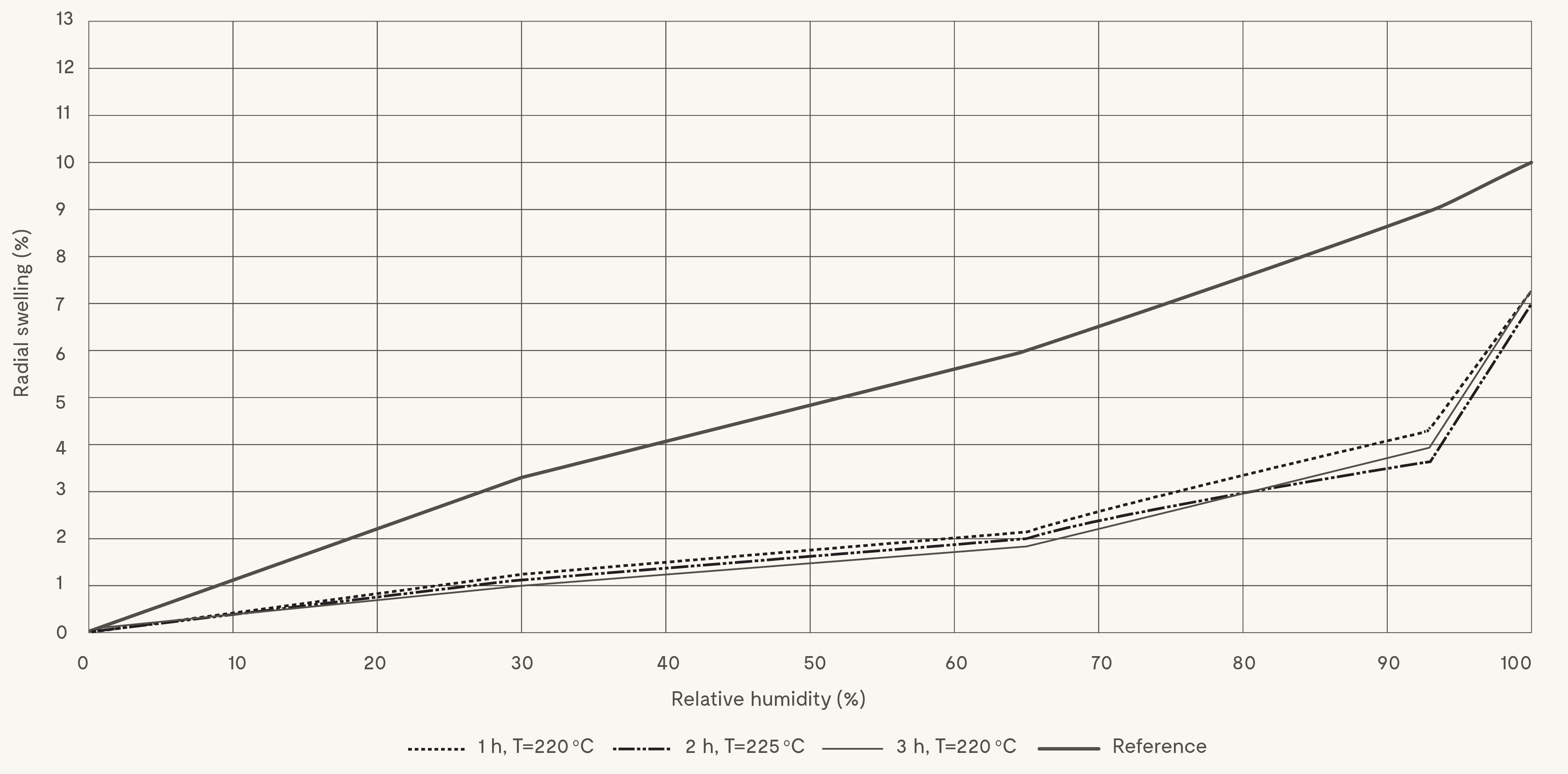

Dimensional Stability

Thermowood products shrink and swell twice as less than the untreated pine or spruce would. They are also much less likely to bend and warp.

This advantage is caused by chemical changes in wood – as the hemicelluloses degrade, the concentration of water-absorbing hydroxyl groups decreases, while the partly broken lignin polymer bonds eliminate the wood fibre tensions. Consequently, the dimensional stability of thermally modified timber improves significantly, compared with untreated wood.

This quality makes Thermowood an ideal choice for contemporary architecture – graphical facades, solar shades, hidden-fixing decking or clean-lined interiors.

Note

Due to its organic nature, under outdoor conditions, Thermowood could incur cracking. Although thermal modification reduces the wood fibre tensions, it does not eliminate the physical phenomenon of water getting into micro-ruptures and reacting to temperature fluctuations, which might cause timber cracking.

Radial swelling of spruce as a function of relative humidity (source: VTT).

Tangential swelling of spruce as a function of relative humidity (source: VTT).

(Brolis Timber factory. Project: Regina Venckievič, Rita Tamulevičiūtė, Erinar, UAB; Photo: Vaidotas Darulis, 2023)

Sustainability

Raw material for BROLIS TIMBER Thermowood is sourced from the renewable forests of Northern Europe. The PEFC label guarantees that wood is grown in the area of responsible forestry.

Thermowood is a natural product, completely free of any additive chemicals. The qualities of wood are modified exclusively by heat, water and steam in a precisely controlled environment. Thermowood is an exceptionally ecological and much cheaper alternative to all the exotic wood species on the market.

Timber is a very sustainable building material, in general, while Thermowood – due to its prolonged lifecycle, non-polluting production and no-coating maintenance option – is an outstanding front-runner. During their growth, trees absorb and store carbon dioxide in their trunks and branches. Uniquely, even the fallen trees, transformed into timber products for construction or carpentry, continue to act as carbon storages for decades. Using timber in construction is proven to reduce the carbon footprint of buildings compared to other building materials, meaning that wood offers great potential to revolutionize the greenhouse gas emissions of the industry.

-

Natural and Healthy Choice

Thermowood is deprived of the otherwise naturally present resins and formaldehydes. The treated wood is antibacterial and suitable even for people allergic to natural wood products. Thermowood finishing radiates emotionally positive and calming effect, thus Thermowood oasis are increasingly popular in educational, retail, and business environments, as well as contemporary interiors.

-

Aesthetic Quality

Thermowood surfaces have soft texture and pleasant scent. The colour is caramel brown throughout to the very core. The higher the processing temperature, the darker the tint. Usually Thermowood is produced from a dense Nordic pine or spruce, and its surface is subtly endowed with the natural structural patterns such as knots and wood grain. When exposed to UV radiation, Thermowood will turn natural grey. Alternatively, the natural tint can be preserved or changed by coating the surface with pigmented stain or paint.

-

Easy Maintenance

After the thermal treatment, wood becomes free of natural resins, which completely eliminates the problem of leaching sap. Thermowood makes an excellent surface for any coatings, extending their service time significantly.

However, due to its natural durability (Durability Class 2), coating Thermowood is only an option, not an obligation. When exposed to the outdoor elements, it acquires a greyish tint, but does not rot. It offers a perfect way to minimise maintenance costs in a variety of cases – from large public spaces and block apartments, to countryside houses and eco-cottages in the wild.

-

Better Thermal Insulation

Studies indicate that thermal modification reduces thermal conductivity, which means that Thermowood is 20–25% more efficient thermal insulator than regular pine or spruce. The VTT research shows that the thermal conductivity coefficient for a thermotreated pine is 0.099 W/m K, in comparison to 0.12 W/m K for the unprocessed one. Because of this, Thermowood is economically beneficial when used for structures such as exterior doors, exterior cladding, windows and saunas.

Other Qualities

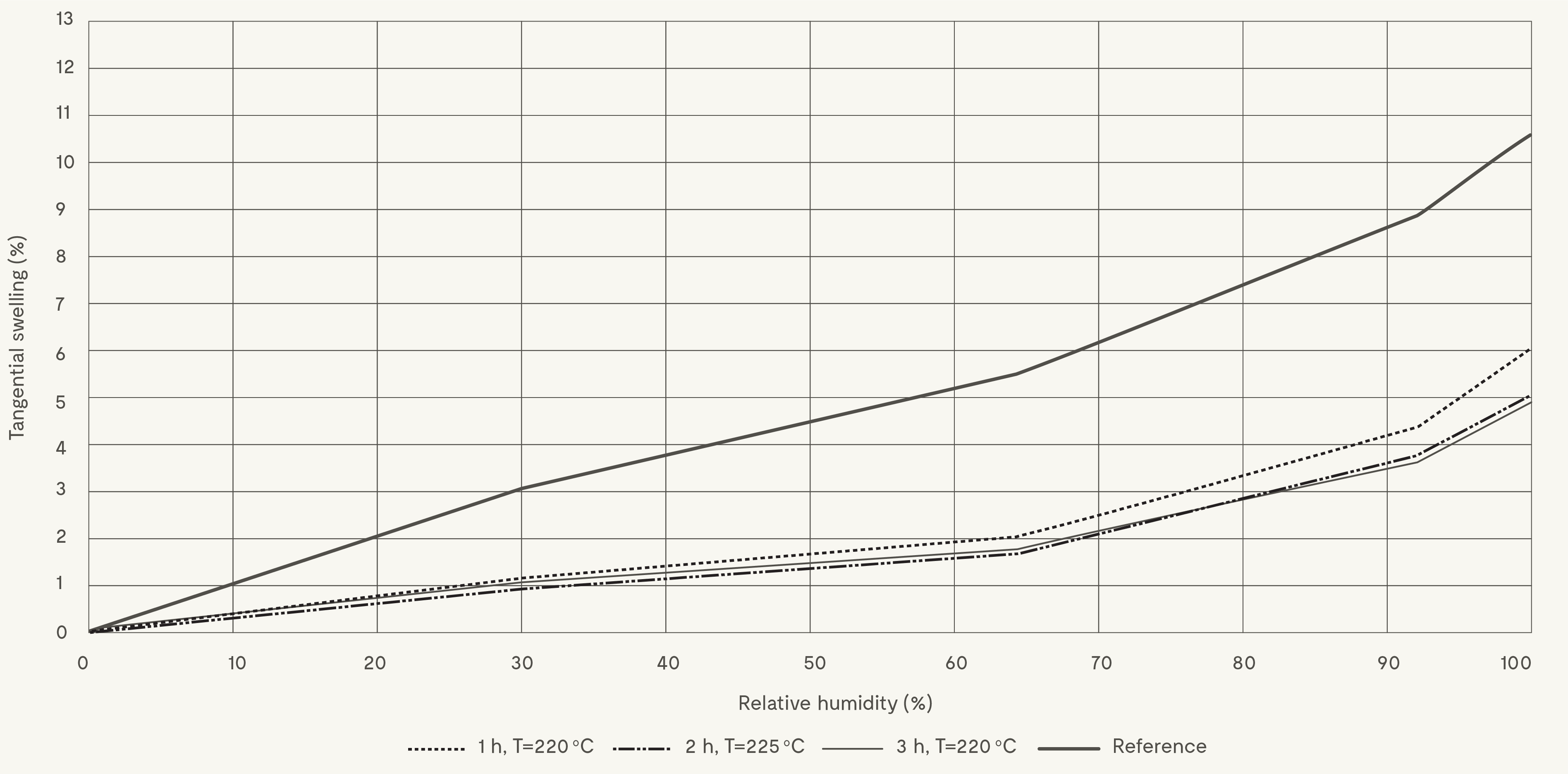

Equilibrium moisture content

Thermal modification reduces timber’s equilibrium moisture content to 4–7%. Even in humid outdoor conditions (+20’C, RH 85%), the relative moisture level of Thermowood reaches only around 10% (EN 13183). Figure (below) shows the impact of thermal modification on the equilibrium moisture content of spruce. At high temperatures (220°C), the equilibrium moisture content is halved compared with untreated spruce.

The impact of relative humidity on the equilibrium moisture content of thermally modified spruce (source: VTT).

Wood Density

Thermowood has a lower density than unmodified wood. This is the consequence of wood losing some of its compounds during thermal modification. With the equilibrium moisture of 6% (+20’C, RH 85%), the density of our Thermowood ranges from 380 to 450 kg/m3, slightly varying from the structure of wood in a specific batch. The density values settle around 10% lower compared to the untreated northern pine or spruce.

Wood density has direct impact on screw holding strength. While nail holding strength appears to be the same to that of untreated wood, due to Thermowood’s lower density, the screw holding strength proves to be 10-20% lower than in regular wood. The results are much better when smaller, pre-drilled holes for the screws are in use.

Fire Resistance

Compared with standard timber, Thermowood causes a smaller fire load and its smoke production is lower. This is also due to lower density and smaller amounts of wood constituents and extractives.

According to the European classification standard, Thermowood is classified as D-s2-d0. When treated with fire retardants, the fire class can be brought up to Class B (B-s1-d0).

Plasticity

After being treated to the Thermo-D class, Thermowood loses its plasticity and becomes more brittle, therefore, unsuitable for heavy weight bearing constructions, unless additional support is provided.